Manufacturing Facilities

The organization has a state-of-the-art electrical control panels manufacturing unit, which is well equipped with all the latest machines and technologies. All the machines are operated by a team of experienced technicians, which has the requisite experience behind them. Our power control panels manufacturing unit is well.

integrated with several units such as a fabrication section, an electrical wiring & assembly section and an in-house testing & measuring facilities.

WE HAVE FOLLOWING IN-HOUSE FACILITIES

🇯🇵 Amada CNC Machine – Precision That Powers Performance

DS Engineering and Services proudly leads Odisha's factory sector with the first integration of the advanced Amada CNC Machine from Japan. This technology revolutionizes precision sheet metal fabrication for electrical panels.

🔧 Key Highlights:

- Micron-Level Accuracy: Perfect punching, cutting, and bending for electrical integrity & safety.

- Superior Aesthetics & Ergonomics: Flawless finish, symmetrical layouts, and easy wiring.

- Repeatability & Reliability: Identical quality for batches of 10 or 1,000 panels.

- Fast Turnaround: High processing speeds without compromising quality.

- Optimized Material Utilization: Minimal scrap, sustainable production, cost-efficiency.

⚗️ 9-Tank Powder Coating Technology – Built to Last, Engineered to Impress

Our in-house 9-Tank Powder Coating System extends panel life, enhances durability, and provides world-class finishing quality.

🛡️ 9-Step Advantage:

- Degreasing → Water Rinse 1 → De-rusting → Water Rinse 2

- Activation → Phosphating → Water Rinse 3 → Passivation → Final DI Rinse

🎯 Benefits:

- Rust-Free for Years: Excellent corrosion resistance for harsh conditions.

- Consistent & Durable Finish: No peeling, cracking, or discoloration.

- Enhanced Safety: Added insulation minimizes surface conductivity.

- Eco-Friendly: Zero-VOC compliant, sustainable chemicals.

- Value-Added Performance: Longer lifespan, reduced maintenance costs.

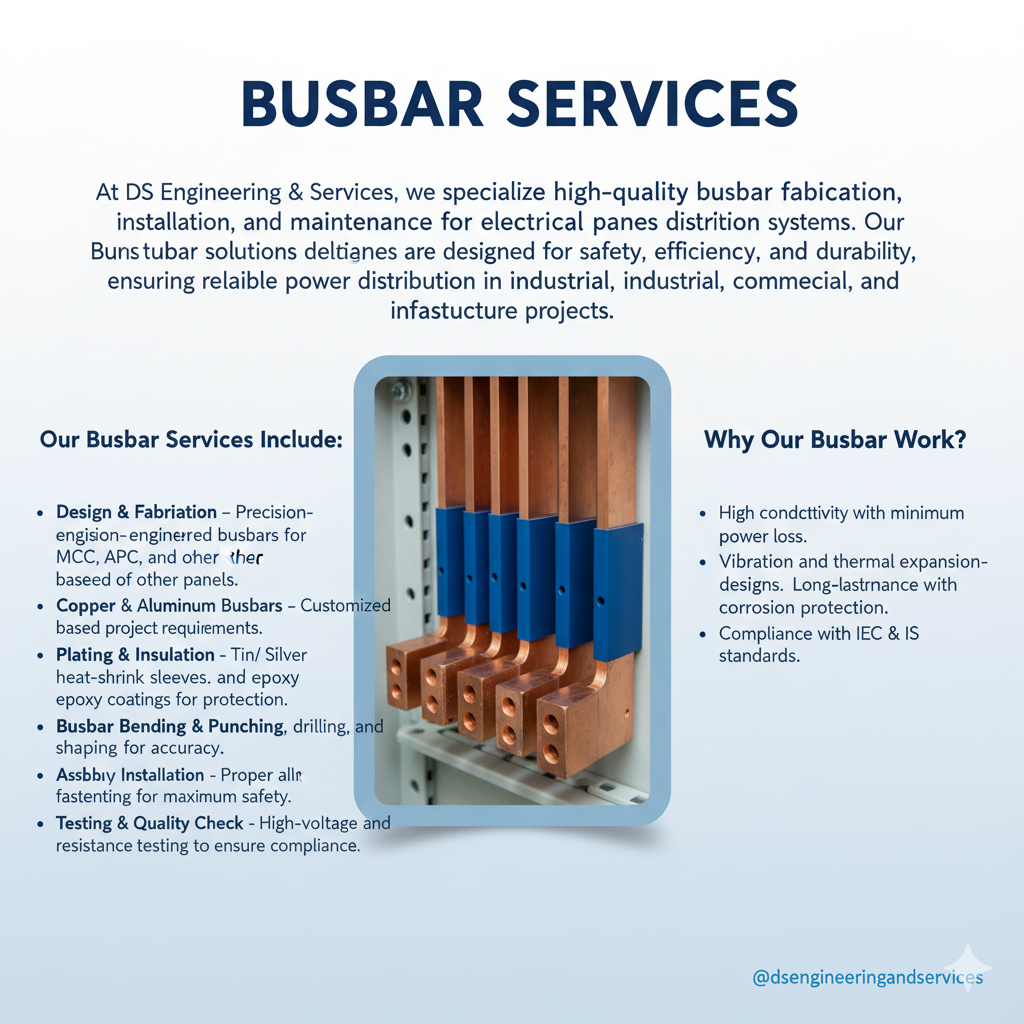

⚡ Busbar Work – Reliable Power Distribution

At DS Engineering & Services, we specialize in high-quality busbar fabrication, installation, and maintenance for electrical panels and distribution systems.

🔧 Our Services Include:

- Design & Fabrication: Precision-engineered busbars for MCC, PCC, APFC, and other panels.

- Copper & Aluminum Busbars: Customized solutions for every project.

- Plating & Insulation: Tin/Silver plating, heat-shrink sleeves, epoxy coatings.

- Busbar Bending & Punching: CNC-based shaping for accuracy.

- Assembly & Installation: Safe alignment, fastening, and support.

- Testing & Quality Check: High-voltage & insulation resistance compliance.

🎯 Why Our Busbar Work?

- High conductivity with minimal power loss.

- Resistant to vibration & thermal expansion.

- Corrosion-protected for long-lasting performance.

- Fully compliant with IEC & IS standards.

🔌 Electrical Wiring – Safe, Durable & Efficient

We deliver safe and efficient electrical wiring solutions for industrial, commercial, and residential projects.

Key Features:

- High-quality cables & accessories

- Structured & organized wiring layouts

- Skilled installation with safety compliance

- Testing & quality assurance for reliability

✅ Safe • Durable • Efficient

⚡ High Voltage (HV) Testing – Certified for Performance

We provide reliable HV testing services to ensure the safety and performance of electrical panels, cables, and equipment.

Key Benefits:

- High-voltage withstand & insulation testing

- Detection of weak points, leakage & breakdown risks

- Ensures compliance with IEC/IS standards

- Improves safety, reliability & equipment life

✅ Tested for Safety • Certified for Performance

🧪 Testing Services – Accurate & Reliable

We conduct comprehensive electrical tests to ensure safety, reliability, and performance of all panels and systems.

Our Testing Includes:

- Megger Test: Insulation resistance check.

- No Load Test: Performance verification without load.

- Functional Test: Ensures correct operation of control & protection functions.

✅ Accurate • Reliable • Standards-Compliant

Design & Engineering

Our Experienced & Technically sound team of Engineers are always there to fulfill all the technical requirement of customer according to their need and also to suggest the best system for them. Our design team is fully equipped with designing softwares 'SEE Electrical & Auto-CAD'. The motto of our design team is to provide the system having 'Engineering With Perfection' to our customer.

Fabrication & Painting

Our Fabrication is equipped with the modern fabrication facilities to achieve Fast, smooth & well finished structure of panel. Our paint shop having 9 Tank process for pretreatment of CRCA / GI sheet to remove Oil, Dust & any kind of rusting part before doing powder coating. Our Powder coating booth consists of Powder coating chamber, Powder coating guns & Electric Oven..

Our Team

DS Engineering & Services is backed with an efficient team, which is committed to cater to the diverse requirements and demands of the clients. Our team of quality controllers checks the entire range of the offered products on various parameters and hence ensures the optimum quality of offered products.